The screenshots in this tutorial and some of the menus are outdated. A review of gasification models using ASPEN Plus process simulator is given by Puig-Arnavat et al.

Aspen Plus Simulation Of Co Pyrolysis And Gasification Of Plastic And Biomass To Syngas Part 2 Youtube

Aspen has two features in the Data Browser window that can both help and hurt the user.

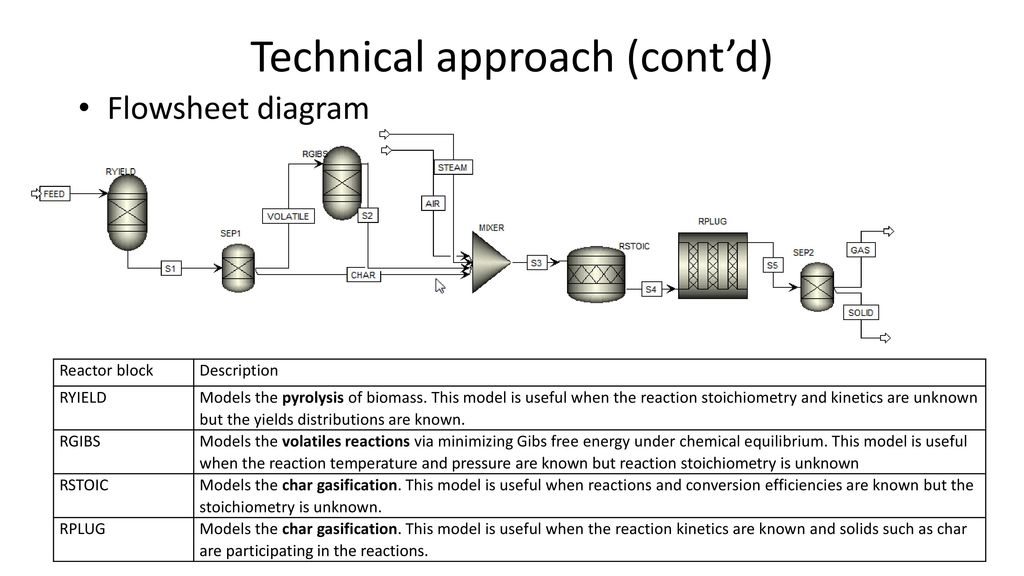

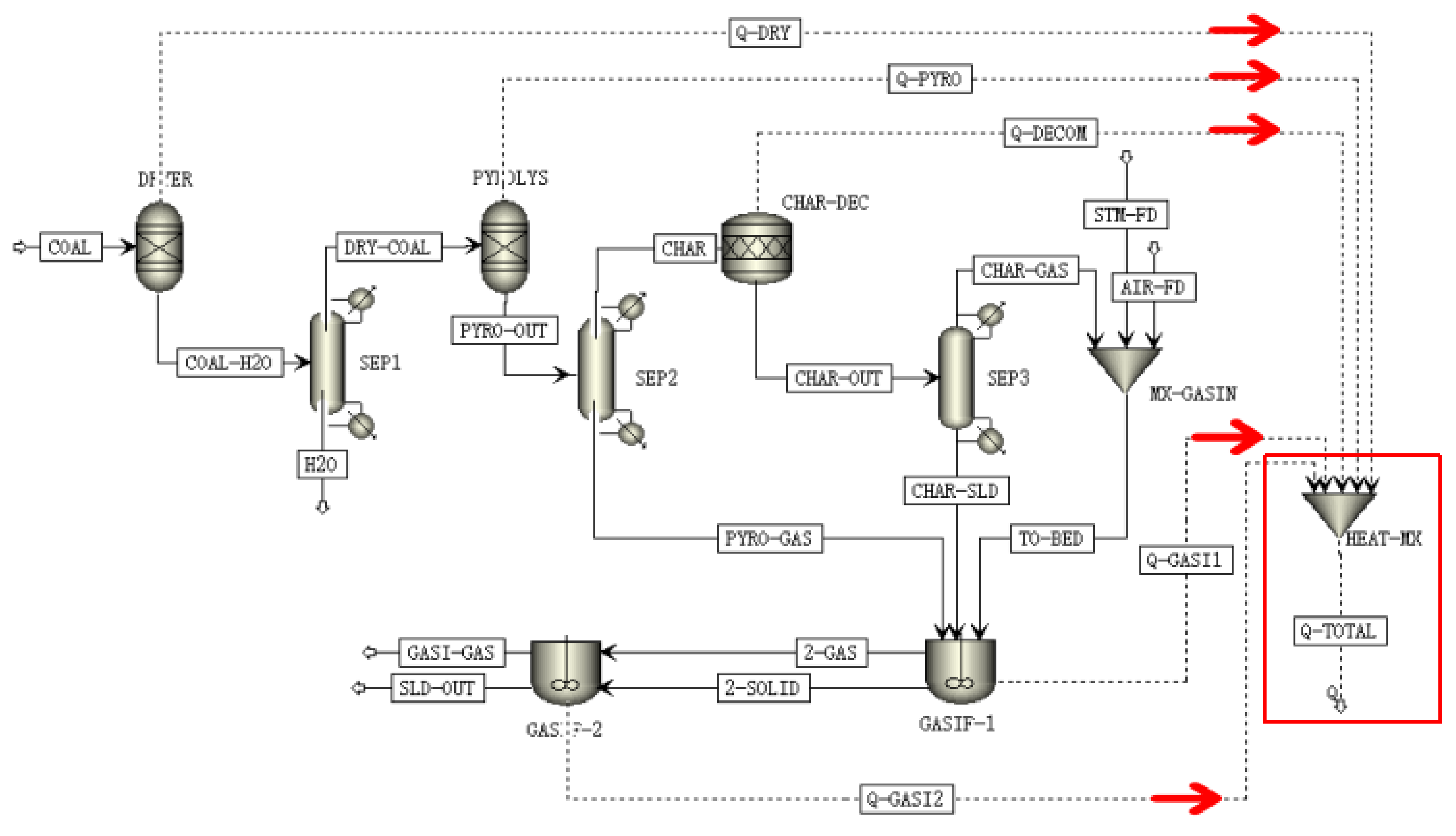

. This window can be opened by clicking on the eyeglass icon or by going to DataData Browser in the Menu Bar. Aspen Plus Getting Started Modeling Processes with Solids This tutorial includes several hands-on sessions to familiarize you with simulating systems containing solids with Aspen Plus. This was done by splitting the gasification process into five different sub processes starting with pyrolysis or decomposition of the feed volatile and non-volatile component separation volatile reactions char gasification and finally solid gas separation.

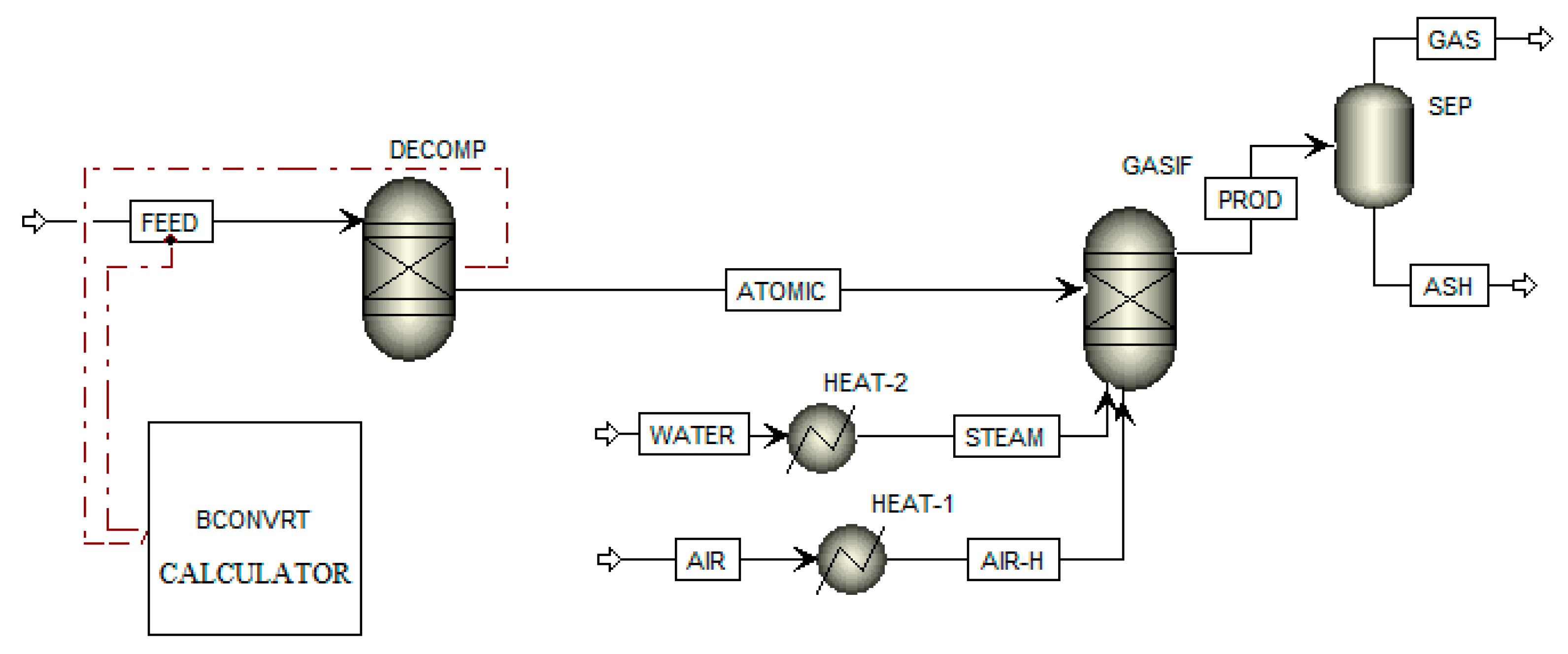

In the pyrolysis process the biomass is devolatilized by heat to char and volatiles. Simulation of sugarcane bagasse gasification has been performed in Aspen plus. However the major steps of working with Aspen are similar to what is depicted below.

Process development simulation. To start either of these packages be sure to look. Aspen_Plus_Model_for_Entrained_Flow_Coal_Gasifierapwz a compound file containing these six files.

Normally undergraduate student projects will involve Aspen Plus or Aspen Properties. I have proximate and. Aspen plus modelling 21.

Join millions of learners from around the world already learning on Udemy. Methanol synthesis simulation 33. Aspen plus simulation of biomass gasification in a steam blown dual fluidised bed W.

A detailed model of the gasification reactor is one of the key points to achieve an accurate process description. Aspen Plus User Guide The three-volume Aspen Plus User Guide provides step-by-step procedures for developing and using an Aspen Plus process simulation model. Aspen Plus Getting Started Building and Running a Process Model Tutorials covering basic use of Aspen Plus.

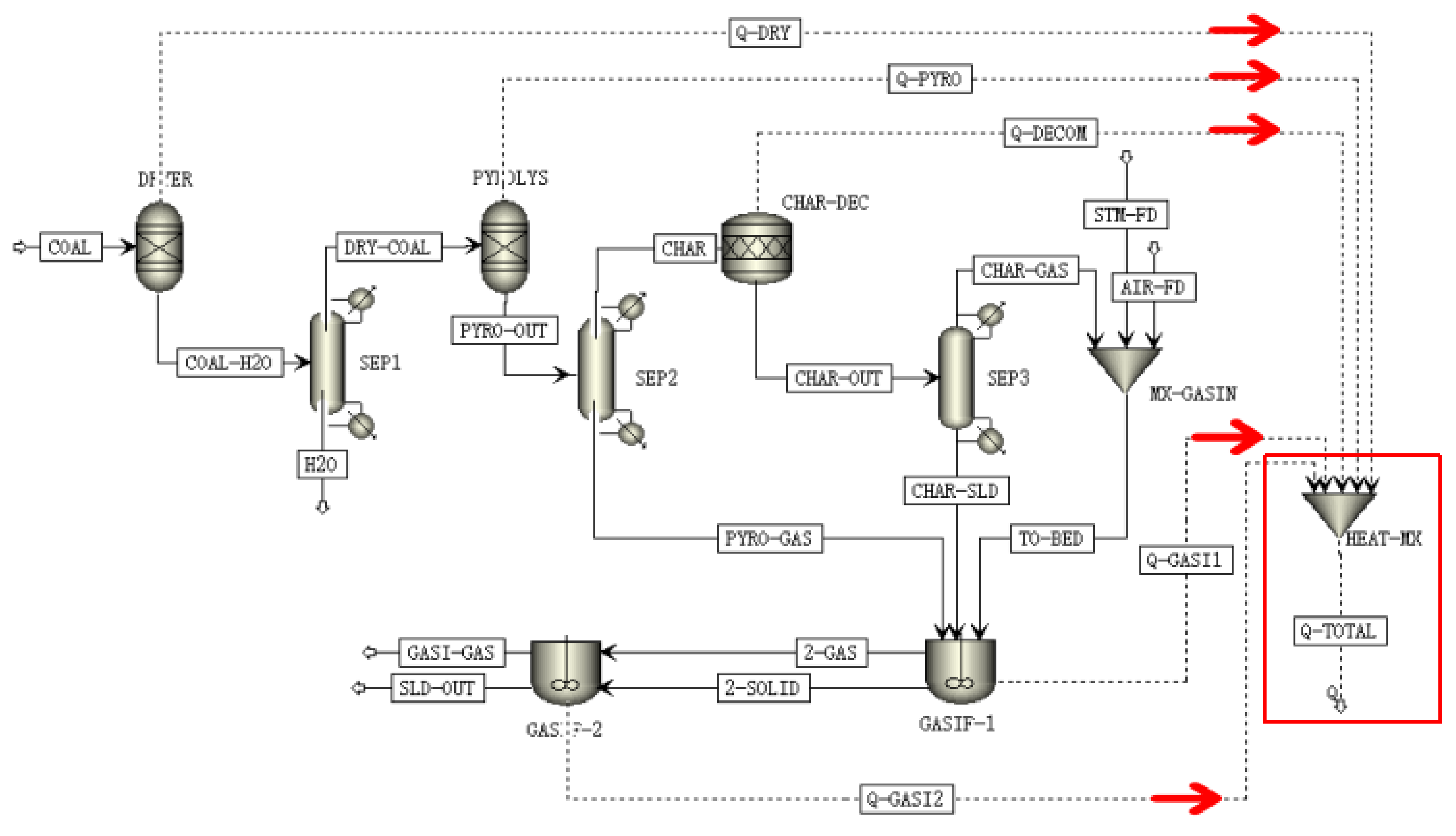

Ad Learn Aspen Plus online at your own pace. Process simulation and sensitivity analysis of indirect coal gasification using aspen plus model By Fahim Uddin and Syed Ali Ammar Taqvi Coal gasification by indirect heating in a single moving bed reactor. Tar was not considered in the model and char conversion was taken as 100.

Biomass gasification using Aspen Plus TABLE OF CONTENTS 1. Methanol synthesis process 3. Gasification simulation model 32.

The aim of introducing steam in the coal gasification process was to increase the heating value of the syngas owing to increasing the H 2 and CO contents. It is possible to utilize the energy through the thermo-chemical conversion processes of pyrolysis and gasification. Vi Aspen Plus User Guide Version 102 7 Physical Property Methods7-1.

Gasification Aspen Plus reaction kinetic 1 Introduction Biomass is an attractive source of energy. Developed a Gibbs free energy minimisation model for steam gasification of biomass to derive the optimum process condition for gasification. GUIExamplesEntrained Flow Coal Gasifier folder of the Aspen Plus installation.

O Aspen_Plus_Model_for_Entrained_Flow_Coal_Gasifierbkp o Aspen_Plus_Model_for_Entrained_Flow_Coal_Gasifierpdf o USRKINf o USRPRESf o. Aspen Plus Simulation of a Coal Gasification Process Geometric Analysis. Aspen Tutorial 1 6 Figure 4.

The gasification temperature is 750 C. All of the data input for Aspen is entered in the Data Browser window. Start today and improve your skills.

A biomass gasification process in ASPEN Plus. The effect of SC was studied by using ASPEN Plus and the simulation results were shown in Fig. A model for biomass gasification in dual fluidized bed DFB reactors by coupling.

The modeling of biomass gasification processes by simulators such as Aspen Plus is a powerful tool to assess mass and energy balances and to optimize process designs. Getting Started with Aspen Plus or Aspen Properties. A biomass gasification process is presented.

Hi I am trying to simulate biomass gasification using Aspen Plus. Completed Mixer Flowsheet Data Input. Aspen Plus 23 is a comprehensive chemical process modelling system used by both academy and industry for design simulation process improvement and optimizationAspen Plus 23has advanced and dedicated functionalities such as detailed heat exchanger design dynamic simulation batch process modelling.

Kennedy12 1 Department of Mechanical Engineering Dublin Institu te of Technology Bolton Street Dublin 1 Ireland 2 Dublin Energy Lab Focas Institute Dublin Institute of Technology Dublin 8 Ireland The efficient utilisation of biomass resources. Depending on the feedstock. The gasification process has been modelled by decomposition of dried bagasse into volatile components and ash followed by partial oxidation and gasification reactions assuming chemical equilibrium where the total Gibbs energy of the system has its minimum value.

I found in lot of articles published people use RYield reactor in Aspen plus to simulate the decompostion. Pressure swing adsorption PSA 23. A prerequisite for the other Getting Started guides Aspen Plus Getting Started Modeling Processes with Solids Tutorials covering the Aspen Plus features designed to handle solids Aspen Plus Getting Started Modeling Processes with Electrolytes.

Aspen Plus Model Flow Sheet For Biomass Pyrolysis Download Scientific Diagram

Process Simulation Of Switch Grass Gasification Using Aspen Plus Ppt Download

Energies Free Full Text Catalytic Coal Gasification Process Simulation With Alkaline Organic Wastewater In A Fluidized Bed Reactor Using Aspen Plus Html

Aspen Plus Modelling Of Air Steam Gasification Of Biomass With Sorbent Enabled Co2 Capture Sciencedirect

Energies Free Full Text Thermodynamic Analysis Of Biomass Gasification Using Aspen Plus Comparison Of Stoichiometric And Non Stoichiometric Models Html

Biomass Gasification Model In Aspen From 12 Download Scientific Diagram

0 comments

Post a Comment